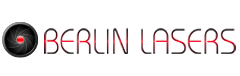

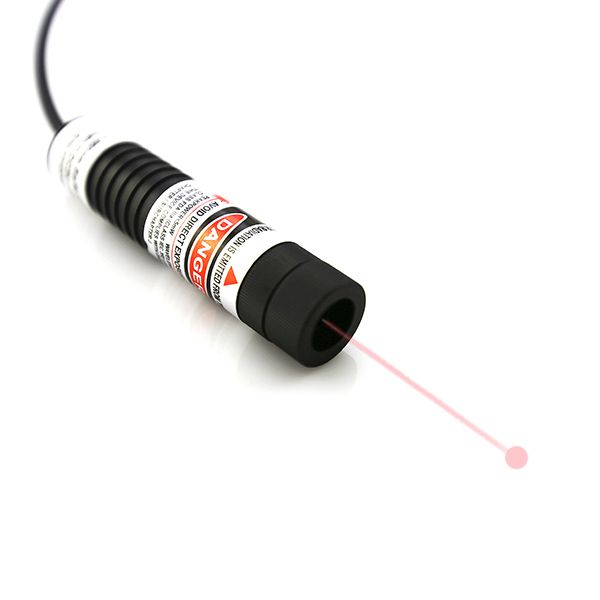

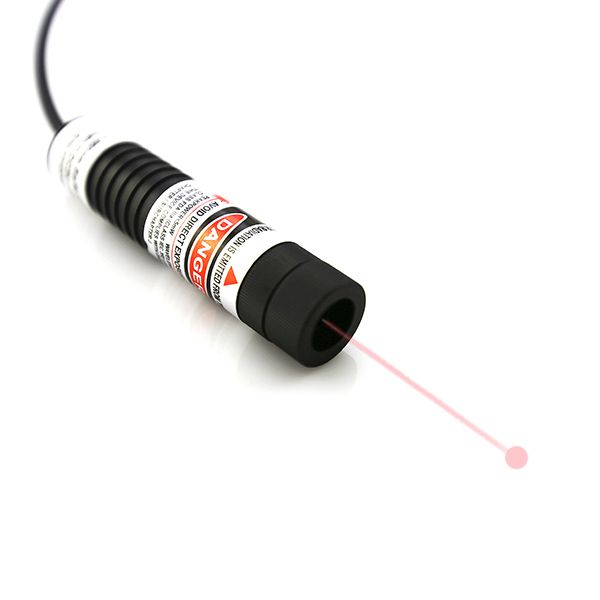

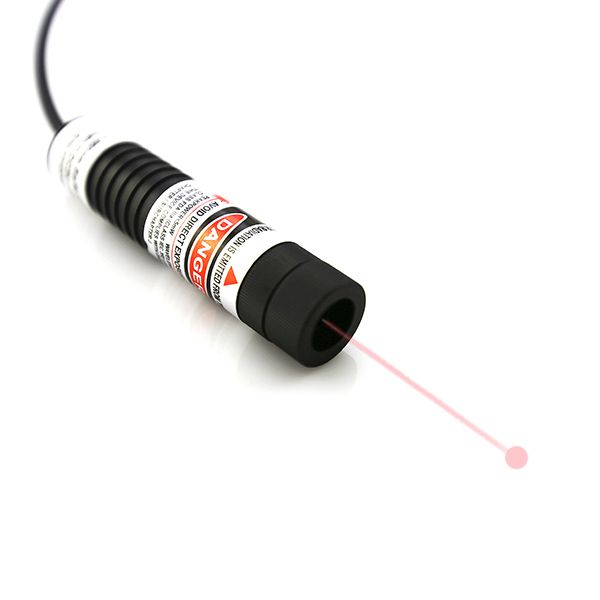

When night version precise dot alignment is in serious need, not able to rely on a simple IR laser pointer or any other manual dot projecting tool, it would make even better job to apply a long wavelength of 980nm made device, such as an infrared laser diode module. It gets a bit longer wavelength than other visible optical spectrum. Basically it applies an import IR laser diode and a qualified optic lens inside a durable metal housing tube, equipped with basic thermal emitting system. On condition that direct diode emission made infrared dot laser alignment makes proper installation or integration into night version device, not limited by any work distance and lighting occasions, it is providing professionals ideal IR laser light source for all security devices conveniently.

The 980nm infrared laser diode module is an ideal light source for security night vision, covert monitoring, and perimeter alarms. It gets featured advantages of no red flash, strong concealment, good penetration, and stable durability. 980nm wavelength has a weaker red blast than 850nm, making the light spot almost invisible. It doesn’t expose the camera or supplementary lighting position at night, preventing theft and vandalism. Employed by an import 980nm infrared laser diode within 100mW to 500mW and 600mW to 1000mW output power, infrared dot laser alignment enables strong penetration and anti interference IR light source generation, not affected by fog, haze, dust, and light rain or snow, providing more stable imaging in complex night time environments.

Either dot measuring work is processing at close or long distance in security field, the concentrated beam energy from a 980nm infrared laser diode module provides good long distance directivity, saving more power than floodlighting, suitable for long term security monitoring. Being made with APC, ACC driving circuit board and basic thermal emitting system inside its durable anodized aluminum alloy housing tube with different dimension, this infrared dot laser alignment supports 24 hours continuous operation, with a lifespan typically up to 10,000 hours, meeting the long term maintenance free requirement of security equipment. It can also be designed with TTL modulation type and supports high frequency switching, enabling strobe lighting and synchronous image capture while reducing power consumption and heat generation.

Core Applications in the Security Field

Infrared Night Vision Illumination and Auxiliary Lighting. 980nm infrared laser diode module is used with night vision cameras, PTZ cameras, and bullet cameras, invisible to the human eye, with no red glow, providing concealed illumination at night, improving image clarity in low-light/completely dark environments.

Concealed Monitoring and Security Detection. IR laser dot is used for perimeter protection, silent monitoring in corridors/stairwells/garages, warehouses, checkpoints, etc., without revealing the device’s location.

License Plate Recognition/Face Recognition Illumination. Precise dot-matrix lighting reduces reflections and overexposure, improving the accuracy of license plate and face capture at night.

Laser Beam and Intrusion Alarm. 980nm infrared alignment laser is used with a receiver to form an infrared warning line, an alarm is triggered upon obstruction, used for perimeter protection of walls, pipelines, and important areas.

Night Vision Aiming and Auxiliary Positioning. Infrared reference dot indication and positioning for security and inspection equipment, usable covertly both day and night.

Tag: infrared laser diode module

Precise Positioning 808nm Infrared Laser Diode Module In The Medical Field

In any type of clear and precise dot indication for all medical treatment and positioning fields, not able to rely on a simple infrared laser pointer or any other manual dot projecting tool, it would be a much better solution to apply a long wavelength made device of a 808nm infrared laser diode module. It always keeps work with moderation IR laser light emission from an import near IR band laser diode, allowing it to penetrate the skin surface and act on subcutaneous soft tissue without the risk of UV/visible light damage. Under operation with correct output power and operating voltage electric power source supply, this direct diode emission made infrared dot laser alignment tool meets the safety standards for medical laser equipment and is suitable for contact-based diagnostic and treatment scenarios.

Basically this 808nm infrared laser diode module applies a AC/DC adapter, not spending prior time on battery change, it can provide continuous infrared light source generation from beam aperture. In addition, it can also be designed with pulse power supply so as to fulfill different users’ need. Being made with an import 808nm infrared laser diode within 5mW to 400mW and 500mW and 1000mW output power, this infrared dot laser alignment is designed with different thermal emitting part. Usually lower power adopts inner cooling system, and high power adopts separate metal heat sink cooling system, thus it always gets sufficient space leaving for tube heat dissipation, and achieves ultra stable and reliable infrared light source and IR dot generation in long term use. It is unaffected by overheating and over current impact as well.

Being made with an adjustable focus optic lens and qualified glass coated lens, 808nm infrared laser diode module can easily make high concentration IR laser light emission, and efficient conversion of increasing accuracy and brightness infrared dot projection at greater distance. The point like IR light spot has strong focusing ability, uniform spot energy without distortion, and precisely target lesions/application points. It is adapted to the energy requirements of different treatment sites. Featured by high electric optical conversion efficiency, this infrared dot laser alignment also gets no significant thermal drift during long term continuous light output, meeting the high-frequency clinical use requirements of medical equipment and reducing equipment maintenance frequency.

Applications in medical treatment fields:

Core Light Source for Laser Therapy Equipment: As the core light-emitting unit of infrared therapy instruments and pain relief devices, the dot-shaped light spot precisely acts on painful areas such as joints, muscles, and fascia.

Core Module of Laser Hair Removal Device: 808nm is the golden wavelength for hair removal. The dotted light spot precisely targets the hair follicle root, selectively absorbing melanin and causing thermal damage, thus putting the follicle into dormancy.

Medical Testing Equipment Light Path Excitation: 808nm infrared laser diode module is integrated into biochemical analyzers and immunoassay devices, it serves as an infrared dotted excitation light source, precisely exciting the fluorescence signal of test reagents.

Precision Diagnosis and Treatment in Ophthalmology/Dermatology: In low-energy ophthalmic therapy and the repair of small lesions in dermatology, the dotted light spot precisely targets the area around the eyes and delicate areas of the face.

Rehabilitation Equipment Supporting Light Source: When used with rehabilitation robots and limb therapy equipment, the dotted light spot precisely targets the damaged limb area following rehabilitation movements.

Minimally invasive surgical positioning aids: In some minimally invasive surgical procedures, infrared alignment laser dot-shaped positioning markers are used to accurately mark surgical incisions and lesion locations, providing visual references for surgical instrument operation and improving the accuracy of surgical procedures.

High Precision Dot Positioning Tool of 980nm Infrared Laser Diode Module

What is an efficient for engineers or professionals to make ultra clear and precise dot indication for those of high precision positioning works? It is far more enough to reach to apply a simple laser pointer or manual dot projecting tool, but making even better job to apply a longer wavelength made device, such as a 980nm infrared laser diode module. It projects invisible and intense infrared laser light from an import 980nm infrared laser diode, equipped with qualified optic lens and thermal emitting system. Whenever this IR dot laser gets constant electric power source supply and proper integration with night version device or equipment, it enables excellent concealment IR laser light emission, which poses no risk of light exposure in security and confidential scenarios, offering higher safety.

Being made with an import 980nm infrared laser diode with different output power range of 5mW to 500mW and 600mW to 1000mW, usually low power infrared laser diode module can meet sensing and fill light requirements, while high power can achieve mild thermal effects, adapting to multi scenario power requirement. After its easy connects with an AC/DC adapter, accepting wide range electric current of 100V to 240V, infrared dot laser alignment always gets highly powerful and intense infrared laser light generation, a small beam divergence angle. After its easy adjustment of laser beam focus lens, it enables highly concentrated energy emission, and high positioning accuracy, suitable for high-precision applications such as ranging and alignment.

In process of long term lasted infrared dot projection, this 980nm infrared laser diode module applies a qualified glass coated lens and glass window in front of beam aperture. It assures low energy consumption and high stability infrared dot projection. In various harsh working occasions, owing to its good thermal control system design, whenever it makes easy integration into small devices, such as wearable devices and miniature sensors, this infrared dot laser maintains stable operation in normal temperature industrial/civilian environments. Whenever users are aware of powerful infrared laser radiation and reflection, it is a key issue to take active laser safety measure and wear proper infrared laser safety goggles, thus it makes good job for all night time security monitoring, industrial automation alignment, laser ranging, and machine vision inspection etc.

Applications in multiple fields:

Security Monitoring: As a core component of infrared fill lights, 980nm infrared laser diode module works with surveillance cameras to achieve covert night vision without visible light, preventing the exposure of equipment location.

Biomedical Field: Used in vein imaging devices to assist medical personnel in quickly identifying subcutaneous veins; adapted to infrared physiotherapy equipment, utilizing the infrared photothermal effect for localized physiotherapy.

Industrial Inspection: 980nm infrared alignment laser is used with machine vision systems to perform component defect detection, size measurement, and positioning; used as the core light source for laser ranging sensors.

Consumer Electronics: Integrated into infrared remote control devices and motion-sensing interactive devices to achieve signal transmission and motion recognition.

Scientific Research and Experimentation: As a basic light source for infrared optical experiments in laboratories, used for material infrared characteristic research, optical sensing experiments, etc.

Stable Wavelength 808nm Infrared Laser Diode Module Applied For Scientific Research Field

If highly precise dot indication is in serious need for those of night version illumination fields, not able to rely on a simple laser pointer or other manual dot projecting tool, it makes a good job to apply a long wavelength made device, such as a 808nm infrared laser diode module. Employed by an import 808nm infrared laser diode and a qualified optic lens inside a durable metal housing tube, only if it gets constant electric power source supply and basic equipped heat dissipation design, it enables high energy density infrared laser light source generation, and converts into increasing accuracy and brightness infrared laser dot projection at different work distances conveniently. When 808nm infrared dot laser is cooperated with night version device, after its proper integration into night version experimental device or equipment, it enables easy reaching, long term lasted and good direction infrared dot indication continuously.

Usually 808nm infrared laser diode module applies an external AC/DC adapter, not spending extra time on alkaline battery power change, it not only gets larger space leaving for tube cooling down, but also achieves increasing brightness and stability infrared reference dot projection as long as 10 hours per day. Owing to its invisible IR laser light emission, this accessory part is always working together with night version device, involving IR laser camera, black and white camera or CCD camera etc. 808nm infrared dot laser alignment maintains small output wavelength fluctuation range, ensuring consistency of experimental conditions and avoids the impact of wavelength drift on the accuracy of experimental data.

Available with an import 808nm infrared laser diode within 5mW to 1000mW and metal heat sink cooling system inside a high duration anodized aluminum alloy housing tube, 808nm infrared laser diode module also gets special use of adjustable focus optic lens. It enables freely adjusted laser beam focus, thus powerful IR laser light is converted into an increasing accuracy and brightness infrared dot projection at a longer distance. It can be adapted to the diverse laser energy requirements of different scientific experiments. Featured by good uniformity and a small divergence angle, the generated high precision beam focusing meets the positioning and illumination requirements of microscopic experiments. Whenever infrared dot laser alignment is interfacing with various scientific research equipment such as spectrometers, microscopes, and fiber optic couplers, it is adapting to the setup needs of different experimental platforms.

Applications in scientific research fields:

1. Fluorescence Excitation and Spectroscopic Analysis: As a commonly used infrared excitation source in laboratories, 808nm infrared laser diode module is used to excite fluorescence signals in specific materials, enabling qualitative and quantitative analysis of material composition and molecular structure in conjunction with a spectrometer.

2. Optical Experiments and Optical Communication Research: Used for performance testing of infrared optical systems, such as lens transmittance and fiber optic transmission loss detection. It can also serve as a signal emission source for short-range optical communication experiments.

3. Basic Biomedical Research: In cell imaging and tissue optical property research, 808nm infrared alignment laser projects infrared spots to observe the absorption and scattering patterns of near-infrared light in biological tissues, providing data support for the development of new medical devices.

Unique Use of 980nm Infrared Laser Diode Module in Lidar Ranging

What is a good solution to make ultra clear and precise dot indication for special working occasions of Lidar ranging? A simple laser pointer or other visible laser device cannot be workable at all. Under operation of constant technical innovation of 980nm infrared laser diode tech and a qualified glass coated lens inside a durable metal housing tube, it is manufacturing into a professional dot measuring tool of a infrared laser diode module. It gets constant electric power source supply and proper connects with an external electric power source supply. Cooperated with night version device or equipment, being used as core laser light source for Lidar ranging, infrared dot laser alignment projects a narrow pulse of infrared laser light towards the target object. The receiving module captures the reflected light signal, and the time-of-flight (ToF) principle is used to calculate the round-trip time of the light signal, thereby accurately calculating the target distance.

980nm infrared laser diode module belongs to a near infrared laser device, owing to its invisible laser light emission, it should only be used as an accessory part. In conjunction with scanning mechanisms, such as galvanometers and MEMS micromirrors, the infrared laser dot scans the detection area along a preset trajectory, achieving 3D modeling of the spatial environment and multi-target distance measurement, providing distance data support for the radar system. Being made with a qualified glass coated lens and adjustable focus optic lens in front of laser beam aperture, infrared dot laser alignment is working well with highly powerful and high photoelectric ability infrared laser light source emission. After conversion of strong light spot focusing and narrow pulse width, it enables accurate capture of reflected signals. Ranging errors can be controlled at the centimeter or even millimeter level, meeting high-precision ranging requirements.

When 980nm infrared laser diode module gets constant electric power source supply, 980nm infrared light can avoid visible light and common interference, is not easily affected by sunlight or ambient light, and can still stably output distance data under complex lighting conditions. Owing to its quick reaching and good direction infrared laser dot projection, it just takes low energy consumption, adaptable to the performance requirements of various ranging fields. Featured by its small size and light weight, this infrared alignment laser can be easily integrated into the overall Lidar system. It meets the requirements for miniaturization and lightweight design, and also has a long service life, reducing radar system maintenance costs.

General applications in Lidar ranging:

Autonomous Driving: 980nm infrared laser diode module is used in vehicle-mounted LiDAR systems to enable vehicles to detect distances to obstacles, pedestrians, and the surrounding environment in 3D, providing accurate environmental data for autonomous driving decisions.

Drone Obstacle Avoidance Equipped in drone LiDAR systems, it measures the distance between the drone and obstacles in real time, triggering obstacle avoidance commands to ensure flight safety. Suitable for drone scenarios such as aerial photography and logistics delivery.

Industrial Ranging and Positioning: 980nm infrared alignment laser is used for distance measurement and positioning navigation of industrial robots, assisting robots in completing tasks such as material handling and precise assembly, improving the accuracy of production automation.

Security Monitoring Distance Measurement: Integrated into security lidar, it detects the distance to moving objects within the monitored area, determines the location and trajectory of intrusion targets, and enhances security early warning capabilities.

Intelligent Transportation: LiDAR used for traffic condition monitoring measures parameters such as vehicle spacing and speed, assisting in traffic signal optimization and traffic incident early warning, thereby improving road traffic efficiency.

How Can 808nm Infrared Laser Diode Module Be Applied in Industrial Processing

How can precise dot indication work is processing for all night version illumination fields? It is not workable at all to only rely on the use of a simple laser pointer or other manual dot projecting tool at all, however, it makes a better job for professionals to apply a long wavelength made device of a 808nm infrared laser diode module. It projects different type of invisible infrared laser beam from a 808nm infrared laser diode. Cooperated with night version device and constant electric power source supply, cooperated with night version machine or device, and proper installation or integration with night version device or equipment, this direct diode emission made infrared dot laser alignment enables easy reaching, high precision and quick response IR dot generation for all industrial processing works conveniently.

Basically 808nm infrared laser diode module applies a durable anodized aluminum alloy housing tube, cooperated with an import 808nm infrared laser diode within 5mW to 400mW and high power up to 500mW to 1000mW. Owing to its special use of a metal heat sink cooling system design, whatever output power it is selected, it gets larger space leaving for tube cooling down, and achieves ultra clear and stable infrared laser beam and infrared laser dot projection under operation with any other night version device or equipment. Whenever it gets strong penetration under workshop smoke and dust, this infrared dot laser alignment is also not effected by strong light/oil pollution, ensuring continuous and stable operation.

Whenever 808nm infrared laser diode module applies a qualified glass coated lens and glass window in front of laser beam aperture, it generates high transmittance and high photoelectric ability infrared laser light source emission at several miles far away. Owing to its low laser beam divergence, together with adjustable focus optic lens design, after its immediate infrared laser light source concentration, 808nm infrared dot laser alignment enables increasing accuracy and brightness infrared reference dot projection at a longer distance, and achieves positioning error as low as micrometers. This industrial stabilized laser device gets good performance of vibration resistant, resistant to high and low temperatures (common operating range -20℃~60℃), long service life.

General applications in industrial fields:

Machinery Positioning: 808nm infrared laser diode module is marking cutting/drilling reference points on lathes, milling machines, etc., enabling rapid tool setting.

Welding/Cutting Alignment: Precisely indicating weld/cutting paths during laser spot welding and fiber optic cutting, improving operational accuracy.

Automated Calibration: Position calibration and trajectory positioning for robotic arms, conveyor lines, etc., ensuring consistency in automated processes.

Assembly Assistance: 808nm infrared alignment laser is providing visual alignment marks during precision parts assembly, reducing assembly errors.

Unique Use of 808nm Infrared Laser Diode Module For Industrial Inspection

What is an efficient job for users to make ultra clear and precise dot indication for all night version illumination fields? It might not be workable at all to only rely on prior manual dot projecting tool, however, under constant technical innovation of advanced 808nm infrared laser diode tech and a qualified glass coated lens inside a durable anodized aluminum alloy housing tube, it is manufactured into a professional dot measuring tool of a 808nm infrared laser diode module. Usually it gets constant electric power source supply from a 5V, 9V 1000mA DC power supply. Not affected by ambient light such as visible and UV rays, stable signal output is maintained in strong outdoor sunlight, under workshop lighting, or in high-temperature, smoke-filled environments, ensuring detection accuracy.

In practical precise dot measuring works, 808nm infrared laser diode module applies an import 808nm infrared laser diode within 5mW to 500mW and high power up to 600mW to 1000mW as its beam emitting source. It gets high photoelectric ability IR laser light source emission. In addition, when it is required to make long term lasted IR dot indication, it has been made with a metal heat sink cooling system and APC, ACC driving circuit board inside a durable anodized aluminum alloy housing tube. In practical long term lasted infrared dot indication, this infrared dot laser alignment tool always maintains stable infrared laser beam emission, and ultra stable and clear infrared reference dot projection as long as 10 hours per day. It also makes sure of noncontact IR dot projection with the workpiece surface, preventing scratches and wear on precision parts (e.g., electronic components and polished metal parts). It is also suitable for high-temperature, high-pressure, and other environments where close contact is undesirable.

When 808nm infrared laser diode module applies a qualified glass coated lens and a glass window in front of beam aperture, on occasion that is used under dust, rain, water or other moisture condition, it still exhibits distinct differences in reflection/transmission across different materials, enabling precise material differentiation and identifying subtle defects, ensuring a balanced inspection depth and accuracy. After its projection of high transmittance, high energy density and low heat generation infrared laser light emission at several miles far away, this infrared dot laser alignment tool can still make ultra stable IR dot generation, which can be working together with industrial machine or device, reducing equipment energy consumption and maintenance costs.

General use in industrial inspection fields:

Defect Detection: By emitting an 808nm infrared spot to illuminate the surface of materials such as metals and plastics, an infrared camera is used to capture the reflected/transmitted light signals to identify subtle surface defects such as cracks, scratches, and bubbles (which are difficult to detect with the naked eye or visible light).

Thickness/Distance Measurement: 808nm infrared laser diode module utilizes the rectilinear propagation characteristics of infrared light, time-of-flight (TOF) or triangulation is used to non-contactly measure the thickness of materials (such as films and plates), the spacing between workpieces, or the positioning distance of equipment.

High-Temperature Environment Monitoring: In high-temperature production lines (such as steel and glass manufacturing), 808nm infrared alignment laser light is less susceptible to interference from high-temperature ambient light and can penetrate the mist/smoke generated by high temperatures to monitor the shape, position, or surface temperature distribution of workpieces.

Material Identification and Sorting: By leveraging the differences in reflectivity of 808nm infrared light across different materials, sensors can be used to identify material types (such as metal and non-metal, different types of plastics) for automated sorting.

How Can 980nm Infrared Dot Laser Alignment Work in Scientific Research?

Comparing with any other visible laser devices, the usual use of a 980nm infrared laser diode module gets much longer wavelength, thus it is always projecting invisible infrared laser beam and IR reference dot from beam aperture, and only allowing proper use as an accessory part of other scientific research used device or equipment. Being made with an import 980nm infrared laser diode and a qualified optic lens inside a durable anodized aluminum alloy housing tube, this 980nm infrared dot laser is working well with high density and high transmittance infrared laser light source emission and ultra compact size infrared reference dot projection within a long extending distance conveniently.

The real use of a 980nm infrared dot laser alignment applies an AC/DC adapter as its electric power source. Owing to its acceptation of wide range electric current of 100V to 240V, this night version used laser device is also applied for a lot of working environments. Being made with an import semiconductor IR laser diode and a qualified glass coated lens, it is not only projecting high density and high photoelectric ability infrared laser light source at long extending distance, but also maintains ultra small laser beam divergence of less than 2mrad. Whatever kind of working surface it is pointing, this long wavelength 980nm infrared dot laser can get highly uniform IR laser dot projection with micron level spatial positioning and meet the precise control requirements of energy or signals in experiments, such as the operation of single cells or nanoscale materials.

When 980nm infrared laser diode module is integrated with experimental equipment such as microscopes, spectrometers, optical platforms etc, there is no complex optical path debugging. It keeps work with high penetration IR laser light source generation into biological tissues and certain polymer materials, which is not easily absorbed by most substances. It is suitable for experimental scenarios that require “non-invasive” or “low damage”. During long term lasting infrared alignment laser dot projection work, the uniquely designed APC, ACC driving circuit board has just protected itself from overheating and over current impact, and ensures long serving lifetime of more than 8,000 hours in proper use. It can greatly maintain low performance attenuation, the repeatability and reliability of experimental data (such as long-term monitoring of the light response changes of samples). owing to its invisible infrared laser light source emission to human eye, it will not cause stray light interference to the signal acquisition of optical detectors (such as infrared cameras and spectrometers). It is especially suitable for experiments with high sensitivity requirements for optical signals.

Main applications in scientific research

Biomedical research: As an auxiliary or direct light source for fluorescence excitation light source, it is used for cell imaging, tissue section analysis, etc. For example, in near-infrared imaging, 980nm infrared dot laser alignment can penetrate deeper biological tissues (reduce scattering and absorption), and cooperate with fluorescent probes to achieve observation of deep structures or molecular activities in living small animals; it can also be used for basic research on photothermal therapy, and selective heating of local cells can be achieved through precise focusing.

Material science experiments: In experiments such as nanomaterial preparation and thin film growth, 980nm infrared alignment laser is used as a precise energy source to regulate material synthesis conditions. For example, the high energy density of its point-shaped light spot is used to induce the directional assembly of nanoparticles in a vacuum environment, or to perform local annealing on semiconductor films to study the relationship between material structure and performance.

Spectroscopic analysis: used as excitation light in experiments such as Raman spectroscopy and infrared spectroscopy to stimulate the vibration or rotation energy level transition of sample molecules and assist in analyzing the chemical composition and molecular structure of materials. It is especially suitable for samples that are sensitive to visible light (such as some organic dyes) to avoid sample damage or signal interference caused by visible light excitation.

Optical system calibration: In the research and development of optical equipment such as lidar and telescopes, 980nm infrared laser is used as a reference light source to calibrate the coaxiality, focal length or aberration of optical components to ensure the measurement accuracy of the equipment.

Industrial Processing Use of 980nm Infrared Laser Diode Module

The 980nm infrared laser diode module is mainly used in industrial processing for high-precision positioning, collimation, marking pretreatment and micro-processing of specific materials. With its infrared band characteristics and stable performance, it plays an important role in the field of precision manufacturing. It applies an import 980nm semiconductor infrared laser diode and a qualified optic lens inside a durable metal housing tube, after easy connects with an external electric power source and proper installation or integration with night version device or equipment, this 980nm infrared dot laser assures high precision, high stability and good direction IR dot positioning results for multiple industrial processing works effectively.

In practical industrial processing works, 980nm infrared laser diode module is operating differently from any other visible laser device or manual dot projecting tool etc. It has good featured advantages of high concealment and no visual interference. This 980nm wavelength belongs to the near infrared band, which is invisible to the naked eyes and will not cause visual interference to operators. It is especially suitable for production lines that require manual auxiliary monitoring to avoid the influence of visible light on observation. Every time 980nm infrared dot laser alignment tool gets constant power source from 5V, 9V 1000mA DC power supply, it begins to work with high penetration IR laser light source to some of non metallic materials, such as plastics and composite materials, which can be used for internal defect detection or deep micro-processing of materials. At the same time, the energy concentration facilitates focusing into a tiny spot.

When 980nm infrared laser diode module applies APC, ACC driving circuit board design inside a durable anodized aluminum alloy housing tube, it bears various harsh working occasions, such as dust, moisture or water vapor etc. Being made with sealed packaging design, it can maintain stable infrared laser beam and infrared reference dot projection in dusty workshops with large temperature differences (some modules support -10~60℃). The extending serving lifetime of infrared dot laser can reach as long as more than 8,000 hours. It gets less output power fluctuation, low performance attenuation, and fulfills the needs of industrial continuous production.

Besides the adoption of a qualified glass coated lens and adjustable focus optic lens, this near wavelength 980nm infrared laser diode module also gets high high circularity of the spot, small divergence angle (divergence angle of some single-mode modules ≤ 1mrad), after collimation, the infrared laser beam can be kept parallel over a long distance (several meters to tens of meters), and the positioning accuracy can reach within 0.1mm. 980nm infrared dot laser alignment always maintains high electro-optical conversion efficiency and short start-up response time, can cooperate with automation equipment to achieve fast switch control, and adapt to the dynamic positioning requirements of high-speed production lines. Owing to its ultra compact structure design, it enables easy carrying, convenient and direct integration with robotic arms, conveyor belts, processing machine tools and other equipment without complex external debugging.

Specific applications in industrial processing

Precision positioning and calibration: In mechanical assembly and automated production lines, 980nm infrared laser diode module is operated as a high-precision reference light source, which provides non-contact positioning reference for the alignment of mechanical parts, guide rail calibration, equipment installation, and ensures that the assembly accuracy of parts reaches the micron level.

Laser welding/cutting assistance: In the micro-welding or fine cutting of thin sheet metal and electronic components, 980nm infrared alignment laser assists in positioning welds or cutting paths, and cooperates with high-power laser equipment to improve processing accuracy, especially suitable for the processing of tiny parts (such as electronic chip pins and precision gears).

Material micro-processing pretreatment: infrared laser light source is applied for surface modification or local heating pretreatment of ceramics, glass, polymer materials, etc., to provide precise energy focusing areas for subsequent processing (such as engraving and etching) and reduce processing errors.

High Photoelectric Conversion Efficiency 808nm Infrared Laser Diode Module

Under operation with a long wavelength of 808nm, being made with an import IR laser diode and a qualified glass coated lens inside a durable anodized aluminum alloy housing tube, it is manufactured into a professional night version used device of a 808nm infrared laser diode module. It generates invisible and intense infrared laser beam directly from an import 808nm infrared laser diode, and configured with inner thermal emitting system and constant electric power source supply. Being made with different dimension tube, after its proper installation or integration with night version device or equipment, this accessory part of a 808nm infrared dot laser enables easy reaching, high photoelectric conversion efficiency and high precision infrared reference dot indication onto multiple working occasions conveniently.

The usual use of a 808nm infrared laser diode module would be working for a quite long time with those of night version device or equipment. Comparing with visible laser devices among all spectrum, 808nm wavelength can convert more electrical energy into light energy, reduce the heat load of the whole machine, save energy and improve equipment performance. This special wavelength enables invisible laser beam emission with narrow spectrum width, and the wavelength temperature drift is small, and it can maintain a stable wavelength output power under different temperature environments so as to ensure the stability and accuracy of the equipment.

Basically 808nm infrared laser diode module has high radiation intensity and has passed lead-free certification, etc. It has strong anti-static ability and long service life, and can work stably in a variety of environments.The inner part of a metal heat sink cooling system and APC, ACC driving circuit board are cooperating well, which enables constant infrared laser beam emission and long time lasting infrared reference dot projection. It gets no effect by overheating and over current impact, and achieves long serving lifetime of more than 8,000 hours. When 808nm infrared dot laser gets low laser beam divergence, the infrared laser beam is concentrated immediately, and the light energy can be concentrated in a specific direction and area so as to achieve long distance IR dot indication and precise aiming easily.

Every time 808nm infrared laser diode module gets constant electric power source supply, it can make continuous IR laser beam emission, which is invisible to the human eye. In the fields of security monitoring, special applications etc, it can work without being noticed, improving the safety and effectiveness of the application. In practical night version precise dot measuring work, it bears wide range operating temperature, and can work in an environment of -20℃ to 60℃. The storage temperature range is -40℃ to 85℃, which can adapt to different working environment conditions. Due to its various advantages, this 808nm infrared alignment laser can be applied to multiple fields, such as medical, security, and industry, meeting the needs of different industries, and has high versatility and practicality. Whenever users are aware of potential thermal energy hurt from IR laser light radiation and reflection, after proper wearing of infrared laser safety goggles, it just assured easy, secured and no danger measurement for all night version fields conveniently.